From the 26th issue of Daf Hakashrus

Ice cream used to be considered a kosher-friendly dairy product. Consisting of fresh cream and sugar, with added vanilla beans/cocoa/ strawberries, it was so easily made kosher.

Those days are long gone, and contemporary ice cream is one of the most challenging of dairy products out there. Let’s see why this is, and try to understand what it takes to manufacture kosher ice cream in the modern era.

We will first examine the ingredients in 21st century ice cream, after which we will take a look ice cream’s manufacturing process.

The basic ingredients comprise the ice cream mix, meaning the blend of liquids and powders which will later be flavored and frozen. Ice cream mix contains (1) cream, (2) possibly skim milk or non- fat dry milk, (3) sweeteners, (4) stabilizers and (5) emulsifiers.

1 CREAM: Although cream is traditionally the fatty portion of milk – referred to in the dairy industry as sweet cream – cream can also be derived from cheese production. This latter type of cream, called whey cream, is particularly kosher sensitive and isactually often used in ice cream production. The reason is that whey cream has a tangier taste than sweet cream, and it is thus not desirable for certain dairy products. Ice cream, which has an abundance of sugar and added flavors, is able to mask the taste of whey cream and is thus a perfect “host” for it. Kashrus agencies need to vigilantly monitor cream sources and assure that problematic whey cream does not enter the manufacturing facility.

2 SKIM MILK/NON-FAT DRY MILK: These ingredients may be added to lower the fat level of ice cream. Although skim milk does not pose a kosher issue, its powdered form, referred to as non-fat dry milk, is occasionally dried from liquid into its powder form on equipment shared with non-kosher substances. This equipment, called spray dryers, is used by some companies to turn milk, juice, liquid chicken fat and shark oil into powders. Hence, non-fat dry milk is kosher-sensitive and is only acceptable under reliable supervision.

3 SWEETENERS: These are typically corn-syrup based sucrose and glucose; they need to be kosher- certified but are less sensitive than some of the other ingredients in ice Regular sugar may also (less) occasionally be used in ice cream, and it poses no kosher concerns.

4 STABILIZERS: These are usually powdered food-grade gums (e.g. locust bean, xanthan, and carrageenan gum) which pose very moderate kashrus Stabilizers contribute to the texture of the finished product, and there is no one rule as to which of these gums, or a blend of them, is used for ice cream production. In former times, and to a lesser extent today, gelatin – which comes from animal bones and hides – was quite commonly used as an ice cream stabilizer. Gelatin is a kashrus landmine, and its absence from most contemporary ice cream is a welcome development.

5 EMULSIFIERS: These ingredients enable the fat (cream), non- fat and air contents in ice cream to blend properly, as well as for ice cream to be eaten smoothly and to soften when The emulsifiers are commonly mono- and di- glycerides (which can come from tallow/animal fat sources) and polysorbate 80 (which contains oleic acid, often derived from tallow). Emulsifiers are very serious business in terms of kashrus, and they are one of the reasons that ice cream absolutely requires tight kosher supervision.

It is obvious that buying ice cream without a reliable hechsher is asking for trouble!

Let’s take a look at the ice cream manufacturing process. Here are the steps involved:

PASTEURIZATION: The ice cream mix is heated to 155 degrees F for 30 minutes or to 175 degrees F for 25 seconds, in order to destroy harmful pathogens. Since ice cream manufacturing plants at times alsohandle other products, the kashrus agency must vigilantly assure that the pasteurization equipment is kosher.

HOMOGENIZATION: Still hot from pasteurization, the ice cream mix is subject to intense air pressure, which breaks fat globules in the cream portion and thereby engenders a smooth texture.

AGING: The ice cream mix is cooled and left to rest for 4-8 hours, enabling the mix to partially crystallize and the mix ingredients to blend better.

FLAVORING: The ice cream mix is pumped into stainless steel vats, and liquid flavors and colors are pumped into the mix here.

FREEZING: The now-flavored and colored ice cream mix is sent into a barrel freezer, and air is pumped into this ice cream mix asit enters the barrel freezer. The air contributes to the finished ice cream product’s feel and ease of consumption.

ADDITION OF PARTICULATES: Small edible pieces, called particulates (chocolate chips, fruit pieces, nuts, etc.), may be added to the product at this point. To accomplish this, the ice cream is sent through a fruit feeder, where particulates areincorporated, via a series of hoppers, with an auger, starwheel and blender, which move theparticulates into the ice cream and distribute them evenly.

PACKAGING AND HARDENING: The ice cream is then filled into packaging, and it is immediately hardened in the containers to 10-13 degrees F below zero. Some ice cream plants manufacture kosher ice cream as well as ice cream with non-kosher marshmallows or gum bits. Since these particulates are added at ambient temperatures, into the fruit feeder, they do not impact the kashrus of the equipment (which will be cold-cleaned afteruse for each type of particulate).

NON-DAIRY FROZEN PRODUCTS

Sorbet, water ice and “ice cream” made from soy, rice and almond milks are common products, which are often labeled as “non-dairy”. Although the mix of these products is non-dairy, it is often pasteurizeed on equipment shared with (real) ice cream and other dairy products, and this equipmentis typically not kashered to pareve status after use for these dairy items. Furthermore, the flavors usedin non-dairy frozen desserts are prone to at times contain dairy subcomponents and/or to be made on dairy equipment. For these reasons, non-dairy frozen desserts can never be assumed to be pareve; the consumer must check with the kashrus agency in each case.

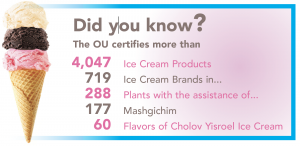

As demonstrated, ice cream kashrus is complex. That is why we recommend always looking for the OU-D symbol! We wish all readers a good Yom Tov!

As demonstrated, ice cream kashrus is complex. That is why we recommend always looking for the OU-D symbol! We wish all readers a good Yom Tov!