Tailorzyme, co-founded by Lars Peter Andersen and Bent Piil Pedersen, is based in Denmark and has been in business since 2015. Their focus is on applications where an enzymatic solution will bring value to their customers and benefit society by more efficiently using raw materials and improving the impact on the environment.

In some cases Tailorzyme will help identify opportunities for using enzymes and work with their customers to develop processes and scale their output for high volume production.

As their name suggests they design enzyme solutions that are customized for their customer’s substrate and process requirements. They also develop new enzymes for industrial applications.

We met with cofounder Lars Peter Andersen via zoom.

Question: Does Tailorzyme produce its own enzymes or buy them from other suppliers?

Answer: We buy them from other high-quality producers so in short, our business model is using our application knowledge in food production and specifically within upgrading side streams into a higher value product that can go into the food stream.

Enzymes in the Fish Industry

Question: Can you give us an example of where you have been able to help a company develop a process that wouldn’t have existed without enzymes?

Answer: We have a lot of business within the fish industry. Roughly speaking 50% of all the weight of fish that is caught globally per year is thrown out or is a low value product because its all of the things you normally would not eat. We are very close to Norway which has a huge salmon production industry with salmon slaughterhouses where the waste has increased in value and has added to companies’ bottom line. To make use of these waste streams for protein and fish oil you need to process it. And that’s where the enzymes come in. In addition to increased income, it is a good story for sustainability which companies can use for marketing.

Many of these companies are run by fishermen who know very little about processing equipment and enzyme processing.

Working in Partnership With Small Companies

Question: So, you have a company, and they produce fish and they know nothing about enzymes. You give them a call and what do you say? What is your pitch to them?

Answer: We tell them we have a laboratory. You can come with your own raw material, and we’ll show you what kinds of products you can make out of it. If it’s a food grade product, you can taste them and with enzymes you can experiment with the process and arrive at a product or a taste profile you’re looking for. We’ll often work with customers in the lab for a week and if they’re interested we can help scale up the production.

We have partnerships with pilot plants that can replicate the process that’s done in the lab. This allows our prospective customers to produce a proof of concept or a pilot product so they can get feedback from their potential customers. They’ll use that feedback to decide whether they’ll have the business if they invest in processing equipment to produce in their own facility. We charge for that process, but those fees are not part of our main business. We want to give these companies the opportunity to explore the market, which will benefit us both.

Our main business model is developing new enzyme applications, so at some point these projects are scaled up and require kilograms of enzymes per hour, adding up to tons per month and year. And we then become an integral part of the project doing optimization work helping them with increased efficiency and cost savings.

Question: Do you have any examples of enzymes that have streamlined the process of production or reduced the amount of processing needed?

Answer: Again, from the fish industry where they produce fish meal which is a powder. It comes from small fish and is costly to make because you need to remove a lot of water.

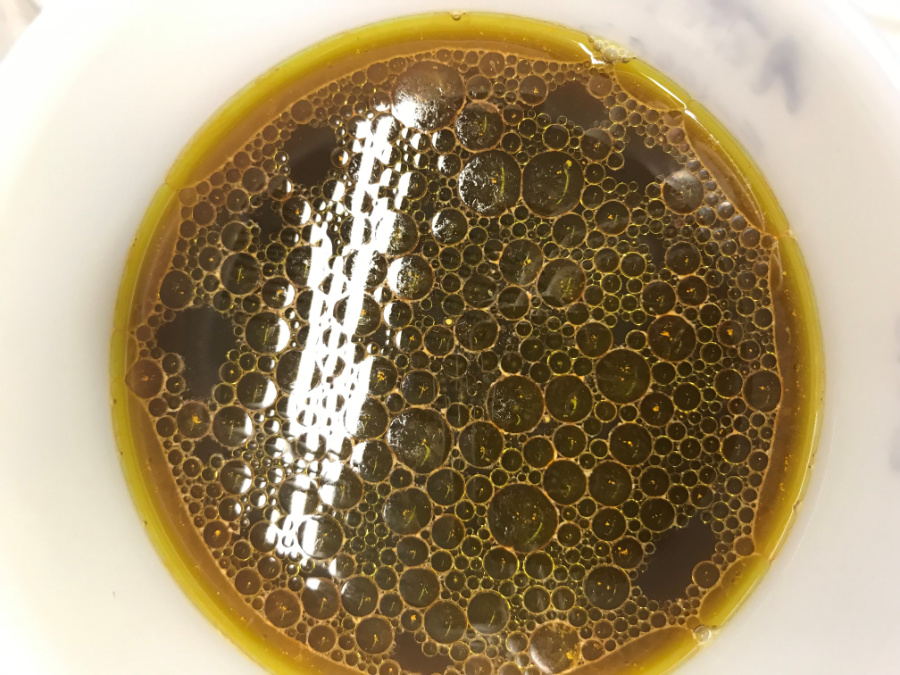

You can remove water from Protein Solutions in two ways. One is by evaporation, and one is by granulation with spray drying. So, while the water evaporates, the product becomes more concentrated and more viscous. Adding an enzyme at that stage as a processing tool reduces the viscosity and saves a significant amount of energy because it reduces the amount of spray drying needed.

Question: what happens to the water in the enzymes.

Answer: It turns into vapor.

Question: Can that vapor be reclaimed?

Answer: Yes. The drying process uses low energy and is heated by waste energy in the plant. So, by using the enzymes and lowering the temperature needed to dry you can use the lower heat vapor produced by the enzymatic process.

Making Enough Protein to Feed the World

Question: Can you talk about some of the areas you’re developing processes for or particular applications?

Answer: The main objective of our company is to make more protein available to the world. The world population is growing and will soon be above 10 billion and that is increasing

demand for protein. There’s a lack of of good proteins so our goal is to make proteins available as food. This can come from existing processes but this can also be from novel foods like the processing of insects or micro algae. These can be converted to oils and proteins and go into animal feed or directly into food. Insects of course would not be a kosher product but others could be. In broader terms it doesn’t matter where a protein comes from. A protein is a protein and we are making protein available.

Exploring the Use of Feathers for Protein

Question: I saw your video in which you turned feathers into liquid. Is that viable?

Answer: Yes, feathers are also a protein. But it’s a very resistant protein called keratin. If you can break it down though, it contains the same building blocks as any other protein

Question: Is the feathers process cost effective?

Answer: Of course, everything needs to be cost effective, but we have not been able to make a business case for it. We have a project in Europe with companies that specialize in sourcing waste streams from the food processing industry. They buy the feathers from a slaughterhouse and then process them creating feather meal. The traditional way of treating feathers for feather meal is to heat them at a high temperature and under high pressure, which produces something burned and caramelized.

So in this case these companies want to make a better tasting better looking feather meal which is produced at lower temperatures and lower energy costs. But the cost of the enzymes needs to be factored in. Bringing down the total cost is what we’re working on.

If feathers can be made cheap to process then you have an abundance of source material. Around seven percent of the weight of a chicken is feathers and it’s usually not processed into conventional feather meal. They just they burn it. So if you have a breakthrough, there’s a fantastic solution for feeding the world.

OU Kosher Supervision

Question: Who made the decision to get kosher certification?

Answer: We often get requests from our customers for kosher certification and we’ve made the decision to support that in the company. We had a consultant helping us who had been working for another enzyme company. He also advised us to work with OU Kosher.

In our case kosher supervision is quite easy because we don’t produce the enzymes ourselves. When we resell, we just need to make sure we have complete traceability and that we handle transport and store all the products according to the kosher certification.

Question: Can you give me an example of a company that’s asked for you to be certified?

Answer: We have a brewery as a customer asking for certification. But it’s not to make beer.

Beer production creates a large waste stream of spent grains and that also contain a lot of good stuff so they are also looking into making syrups for bread and other products. Some of those products needed to be kosher.

We have a brewery that makes most of their profit from the waste streams. They’ll make malt syrups and yeast utilized in bread production. This has a completely different flavor so you get sweeteners that are different than normal sweeteners. You can get some other taste profiles in your bread that are interesting, not a chemical composition and not sugar.

Question: Did you know anything about kosher before you started with the OU Kosher?

Answer: Yes because we have a background working at one of the major enzyme companies producing enzymes that were OU kosher certified.

Question: Are there areas or categories of production that are more amenable or have a greater potential for use with enzymes that people might not be aware of?

Answer: Anyone in the food processing industry with waste streams can benefit from exploring this type of solution. I think they’ll soon find out that enzymes would be part of such a solution.

We’re also able to support smaller companies and help them develop their solutions. The big enzyme companies producing the enzymes have their areas of focus and will not invest in developing a project for a small company. That’s where we come in. We are your partner in development and production.